Aluminum Scrap & Recycling

More manufacturers are choosing aluminum over other metals. Some industries, such as construction, rely on aluminum for its durability, while others depend on its flexibility and conduciveness. Aluminum produces natural oxides, creating a thin layer of corrosion resistance. What's more, aluminum's unique characteristics make it suitable for recycling repeatedly. It maintains its physical and chemical properties even after multiple rounds of recycling and years of reuse. That means recycled aluminum used in production processes today is just as sturdy, flexible and stable as it was decades ago when it first went into a consumer product. It is also 100% recyclable, so there's no waste involved and no material lost over time.

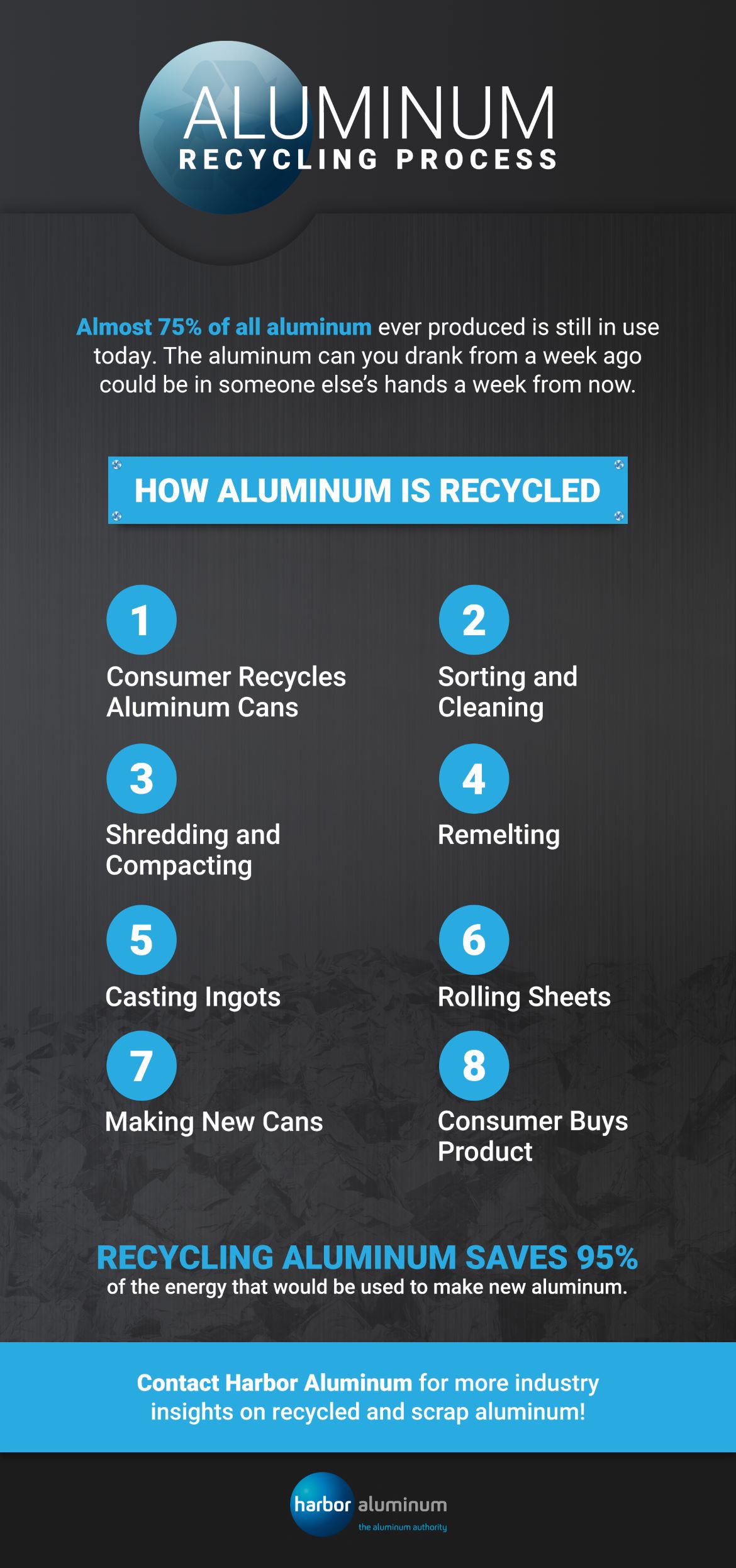

In developed countries, supplies of secondary and scrap aluminum are high, contributing to a large recycling market. The energy cost to recycle aluminum is typically over 90% more affordable than producing aluminum from raw materials. Additionally, nearly three-quarters of all the aluminum the world has ever produced is still in use today. It has cycled through thousands of aluminum products, reducing waste and helping to lower pollution levels.

If your industrial business requires aluminum for its products or produces aluminum as scrap and needs to dispose of it responsibly, recycled aluminum is an appealing solution. At HARBOR, we help navigating price fluctuations and changes in the aluminum scrap and secondary market. We have years of experience consulting companies on how to effectively source scrap aluminum for their industry needs.

Learn more about how HARBOR can keep you ahead of the competition. Explore our reporting options and start receiving the latest aluminum market and scrap metal price updates.

Aluminum Scrap & Recycling Industry Explained

Producers across the aluminum industry pay over $800 million per year for recycled and scrap material. Due to its value, almost three-quarters of all the aluminum ever produced remains in circulation today.

The recycling industry creates and sustains more than 160,000 jobs, with an estimated 5,000 jobs supported by recycling efforts. Recycling contributes over $70 billion per year in economic output for the United States.

How Does the Aluminum Recycling Process Work?

Aluminum is the popular packaging choice for beverage makers and food packaging companies for many reasons, especially printability. Additionally, more than 90% of aluminum from building components and automotive parts undergoes recycling at the end of its life span, though rates for the aluminum used in consumer packaging are lower.

So how does the aluminum recycling process work? Scrap and secondary aluminum are shredded and sorted to remove glass, metal and other debris. Recycled scrap aluminum is liquified at temperatures over 1200°F, poured into molds and formed into aluminum ingots. The same oxides that produce resistance to corrosion appear after contact with the environment. These oxides, known as dross, are removed with a skimming tool. Dross is refined to extract any valuable materials.

Aluminum recyclers progress through a series of steps to accomplish these goals.

1. Collecting Scrap

In the first step of the aluminum recycling process, a professional works with two different types of aluminum scrap — new and old scrap. New scrap is extra aluminum material produced as an offshoot of the manufacturing and fabrication processes. For instance, extrusions or offcuts of aluminum sheets are considered new scrap. Because its composition is known, new scrap can be recycled safely by aluminum smelters.

Old scrap is aluminum that has been used by consumers and discarded. Examples of old aluminum scrap include car cylinder heads, electrical cabling, window frames and used beverage cans. The composition of old scrap may be contaminated and is typically unknown, meaning smelters cannot safely accept the material.

In addition to these two types of aluminum scrap collected during the first stages of the aluminum recycling process, smelters can collect aluminum from other community areas. These include local and regional authorities, scrap merchants, households and other sources.

2. Sorting Scrap

Aluminum scrap is sorted in the second step of the aluminum recycling process. Aluminum smelters group all uncoated aluminum and all coated — lacquered or painted — aluminum together.

Non-aluminum materials are removed in this stage. This done by feeding the aluminum through a sorter — which separates out other distinctive materials like glass and plastic — and a magnet, which removes other metals like steel.

3. Crushing

In the third step, sorted aluminum scrap is compacted by being crushed into bales. This process ensures reduced handling, storage and freight costs.

4. Remelting

Any coated aluminum scrap is processed in a gas-fired rotary furnace. This process removes any coating on the aluminum scrap before it's transferred to the remelter or large furnace.

Uncoated aluminum scrap is directly loaded into a remelter, where it converts into molten form after being heated at high temperatures.

Melting aluminum typically generates a byproduct known as white dross, which contains about 15% to 80% aluminum mixed with impurities. Recyclers generally skim off the white dross to recover its aluminum content.

5. Casting

In the last step of the aluminum recycling process, molten aluminum is cast at high temperatures to form ingots or pieces of the aluminum cast into suitable shapes for processing.

Ingots are then transferred to aluminum manufacturing or processing plants to be made into new products.

How to Recycle Aluminum Cans and Foil

These days, government entities make it easy to recycle aluminum cans. Programs offering curbside or municipal pickup are widespread, as are recycling bins. Residents can throw in items like soda cans, aluminum foil and aluminum baking trays and know these things will go on to aluminum recycling centers and provide life to new products.

Ten states in the United States also allow consumers to turn in their used aluminum cans for cash, providing a greater incentive for recycling. More than a third of all recycled aluminum cans come from the deposit programs in this handful of states.

Local recycling centers are always paying for aluminum, meaning there will be innumerable ways to make a profit or support recycling programs in your community.

What Are the Benefits of Scrap Aluminum?

Aluminum has virtually limitless recycling possibilities. It's possible to melt and reconfigure used aluminum products and materials without compromising quality — you can use it again and again. The metal remains strong, workable and durable. Regarding its properties, recycled aluminum is identical to a new aluminum product.

The lighter weight also improves the energy efficiency and fuel economy of automobiles containing aluminum parts and components. Businesses that purchase aluminum for their manufacturing processes add value to their products and become better stewards of the environment.

The market outlook for the aluminum scrap metal market is positive, as more companies move toward manufacturing with aluminum. The tech, construction and consumer goods markets consistently find new applications for aluminum.

Demand is increasing and there is a large stockpile of scrap and secondary aluminum wasted each year. Estimates by the EPA place the quantity of aluminum consigned to landfills at over 2.4 million tons — almost 2% of all annual landfill volume.

Environmental Impact of Recycling Aluminum

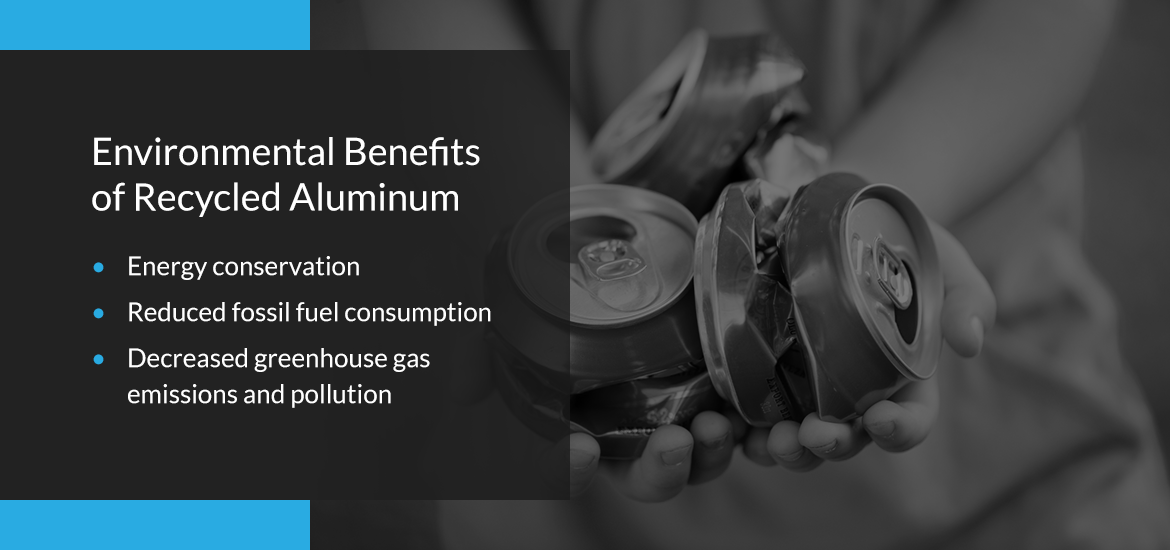

Recycling aluminum saves money and energy compared to producing aluminum from raw materials. Beyond the savings in production costs, recycling is much more energy-efficient than mining operations. As more companies and consumers focus on increasing sustainability, recycled aluminum will emerge even further as the leading metal for manufacturing. Below are some of the environmental benefits recycled aluminum offers:

Energy Conservation

Recycling aluminum saves 90% of the energy required to mine and process primary aluminum. This number is so large partly because extracting bauxite and using it to produce new aluminum is incredibly energy intensive, using approximately twice the amount of energy required to create new plastic. Using recycled aluminum reduces energy consumption and all the environmental harms that go along with it.

Reduced Fossil Fuel Consumption

Reducing energy consumption also means decreasing fossil fuel use. Recycling aluminum instead of creating more primary aluminum reduces the harms associated with fossil fuel burning and leaves more of this finite resource available for future use.

Decreased Greenhouse Gas Emissions & Pollution

Minimizing fossil fuel consumption contributes fewer pollutants to the atmosphere and lowers levels of the greenhouse gas emissions that cause climate change. One wrinkle here is that recycling itself requires fossil fuel consumption and produces carbon emissions, so recycled aluminum water cans, for instance, are not entirely environmentally blameless. However, compared with new plastic water bottles and the carbon costs for producing them, aluminum cans still reduce emissions substantially.

Data & Aluminum Recycling Rates Around the World

Knowing the tremendous environmental benefits of aluminum recycling, we should also consider some relevant data, along with the economic value of recycled aluminum.

The U.S. Environmental Protection Agency (EPA) has reported a substantial body of data about aluminum recycling. According to the EPA, the United States generates 3.9 million U.S. tons of aluminum waste which accounts for approximately 1.3% of all municipal solid waste generation.

Of the 3.9 million tons of aluminum waste produced in the United States, 2.66 million tons of it went to landfills, while only 670,000 tons went for recycling. An additional 560,000 tons underwent combustion with energy recovery.

Recycled aluminum tends to bring in excellent prices. However, aluminum recycling rates around the world tend to fluctuate with supply and demand. For the most reliable and up-to-date information, you'll want to work with premier aluminum specialists with access to the latest global market intelligence and price outlooks.

Choose HARBOR to Help You Navigate the Aluminum Scrap & Secondary Market

To buy or sell environmentally friendly scrap and secondary aluminum for industrial processes, work with HARBOR Aluminum. We are the only market intelligence firm that specializes in aluminum pricing and forecasting. We don't work with other metals, meaning we can focus all our energy and resources on providing the best aluminum data possible.

We offer value for businesses by educating our clients about true market aluminum values. We provide detailed, accurate aluminum industry data to help clients navigate the field and its submarkets worldwide. We also help clients understand the aluminum industry price outlook and devise sound investment, purchasing and marketing strategies. Once we've accomplished all that, we connect our clients with the right industry supplier or customer for their products and services, securing economically beneficial partnerships for both buyer and seller.

Our aluminum consulting services includes scrap aluminum pricing and market intelligence to keep you informed with the most up to date information.

Subscribe to our market intelligence reports for more insights, or contact us today to learn more.